Find a Function

Are you interested in knowing the functions our machines are capable of, you can read all about them right here.

- Buffer

- Cleaning in Place

- Cooking

- Cooking - Direct Steam

- Cooking - Indirect Steam

- Cooking - Indirect with Electricity and Water

- Cooking - Indirect with Pressure (Exchanger System)

- Cooling

- Cutter

- Defrosting

- Direct Steam Injection

- Dispersion

- Dissolving

- Emulsifying

- High Shear Mixing

- Homogenizing

- Inline Mixing

- Lifting

- Melting

- Mixing

- Oil Storage

- Pre-Mixing

- Pressure Cooking

- Rasper

- Reduction

- Shredding

- Stirring

- Ultra High Temperature Treatment

- Vaccum

- Weighing

Buffer

If you invest in a process line from Limitech, a buffer tank application could be of your interest. By implementing a buffer tank in your system, you can create a continually process by for example having a buffer tank after your mixers. Depending on your set up and needs, a buffer function could therefore be a highly efficient additional function to your process, in this relation we advise a conical or cylindrical buffer tank.

Cylindrical buffer tank: The cylindrical buffer tank is ideal for storage or for mixing if your mixing capacity is high.

Conical buffer tank: Whereas the conical buffer tank is ideal for storage if your product is very viscous. The conical shape of the tank provides you with a tank which is shaped to benefit your product in the highest possible way.

Cleaning in Place

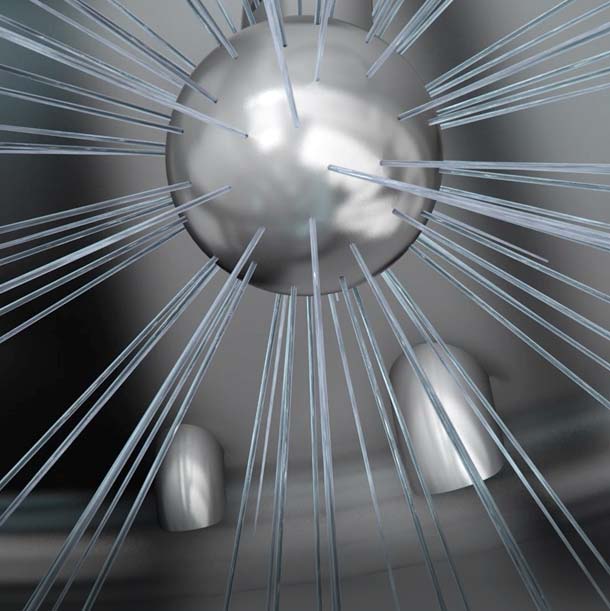

Limitech’s ”Cleaning in Place” also called CIP secures efficient, safe and fast cleaning. The system makes sure all particles are flushed out and every surface thoroughly cleaned. CIP is defined as an disassemble and manual cleaning of the internal parts of the equipment, which was the procedure up to around the 1950s. CIP is traditionally carried out with using CIP units from where the required amount and flow can be achieved. There are several issues to consider, flow requirements and number of required internal spraying devices for tank cleaning. Here also taken in mind the size of the tank and its complexity. Also, the pipe size that has to be cleaned is in order to determine the required flow as the pipes are required a minimum flow speed of 1,5 m/second to create a turbulent flow. CIP units can be a part of a CIP plant which can contain several larger tanks for clean flush water and recollected water used for pre-flush purchases only, cold and hot water tanks etc.

The CIP system comes in two different systems – the one that cleans with water and the one that cleans with both water and chemicals. The choice of system will depend solely on your process.

Cooking

Foods mainly consists of water, fat, protein and carbohydrates. When cooking, you change the process of the foods chemistry by transferring energy to achieve the desired flavor, texture, tenderness, appearance and nutrition. The customized solutions from Limitech can be built with a variety of different cooking functions which will be described in the following.

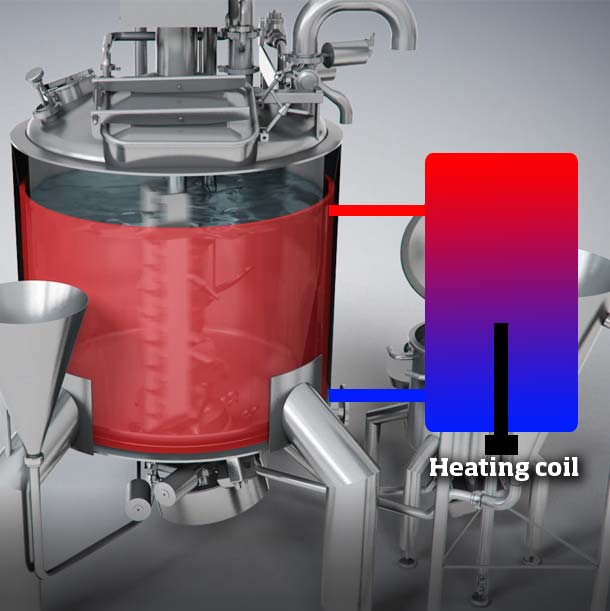

Indirect heating: Steam is blown into the dimple jacket to heat the product without direct contact with the product. This gives a gentle heating process that is easy to control.

Features: Steam is running through the dimple jacket around the tank and heats the product without direct contact.

Advantage: Efficient heating with indirect steam and no added condensate from the steam to the product.

Benefit: Indirect heating with steam and easy control of recipes.

Cooking - Direct Steam

Steam is injected into the vessel, typically used for ketchup and sauces. It gives a very rapid heating with no risk of burning on wall surfaces. This heating process is typically faster than indirect heating.

Feature: Steam is injected into the vessel and directly into the product.

Advantage: Rapid heating of the product and no burning on wall surfaces.

Benefit: More product per hour and better product without aftertaste and avoids waste.

Cooking - Indirect Steam

By cooking with indirect steam, the steam is not going directly into the tank. Instead it goes via pipes in the cap around the tank which ensures your product not to burn on the surface wall. This is also an ideal cooking method if your processing a sensitive product or for products than need to heat more slow over time, as the indirect heat is a bit slower to heat than with direct steam.

By using indirect steam you also ensure no water gets into the product as can happen when using direct steam.

Cooking - Indirect with Electricity and Water

Indirect heating with electricity and water is a heating system that runs slower in the form of a lot of kilowatts. This heating system is characterized by the fact that it is often used if there is no access to a steam boiler and it therefore runs on electricity. This is a slower heating process compared to the other listed heating systems; however, an advantage for certain product types.

Contact Limitech, and in collaboration with us find the perfect heating system for you and your process and facilities. Should you have any questions, our technical advisors can advise you on what we believe makes the best sense for you and your process.

Cooking - Indirect with Pressure (Exchanger System)

Indirect heating with electricity and water is a heating system that runs slower in the form of a lot of kilowatts. This heating system is characterized by the fact that it is often used if there is no access to a steam boiler and it therefore runs on electricity. This is a slower heating process compared to the other listed heating systems; however, an advantage for certain product types.

Contact Limitech, and in collaboration with us find the perfect heating system for you and your process and facilities. Should you have any questions, our technical advisors can advise you on what we believe makes the best sense for you and your process.

Cooling

The cooling system is cold or iced water used directly in the dimple jacket. This system reduces cooling time rapidly and in combination with our vacuum system you can reduce the cooling time even further. Please ask for more specific information regarding your product. Cooling is used to reduce the temperature of the food from one processing temperature to another or to a required storage temperature. Cooling preserves food by slowing down the growth and reproduction of microorganisms and the action of enzymes, and through the fast cooling increases shelf-life of the product.

Advantage:Cools of the product in the same tank in which you have been cooking.

Benefit: Fewer machines needed as you can heat and cool in the same machine, which safes space at production sites.

–More gentle method compared to a surface scrape heat exchanger. The cooling

process can be hold in one or several different tanks depending on your process.

Cutter

Whatever your process might be Limitech’s ‘Cutter’ can help you tackle the process. Ideal for the process of cutting different products in different sizes. The unit have long, covered mixing bowl and high horsepower motors, allowing them to handle a bulk amount of food at one time.

The cutter mixers are the perfect choice for your process and factory. Not only will these units mix, puree, chop or cut your foods efficiently, but they’ll also ensure that these tasks are done efficiently and thoroughly.

Direct Steam Injection

With direct steam injection, steam is going directly into the tank with the product. This makes the cooking and process of heating of the process go very fast whereas indirect steam is slower. This makes your process quick and is easy to control the direct steam injection. However, whether you should choose indirect og direct steam depends on the specific product and processes you have.

Each steam injection is highly effective depending on your needs.

Dispersion

A chemical dispersion is a mixture consisting of more than one phase, were at least one of the phases is finely divided in another either as a suspension, colloidal mixture or solution. All phases in which Limitech for decades has studied and cracked the code for, to ensure a perfect, efficient and homogenous dispersion as it is of essence to avoid lumping during dispersion of powdered ingredients. When it comes to dispersion ingredients there are two different kinds; the one that are easily dispersion able and the other that are not.

At Limitech we know, that when adding powdered ingredients into food processing lines, the use of the right mixing equipment not only can prevent lumping, but can also increase productivity, enhance product quality and reduce energy costs. Difficult-to-disperse powders pose challenges for manufacturers all over the world because of the formation of lumps also called “fisheyes”. Limitech has for decades mastered the easy as well as difficult disperse products resulting in mixers highly capable for dispersion of all kinds of products.

Find your solution on the product page

Dissolving

For decades, Limitech has refined its knowhow within dissolving and today masters it to perfection. We specialize in connecting it to a solution perfect for your factory and processes.

Some substances dissolve when mixed with a liquid like water. When the blend dissolves it may look like it has vanished while in fact it has mixed with the water to make a transparent liquid. Through years we have gathered a high level of expertise of dissolving products in liquid form for different processing and end results both within industries as food, pharma, chemical, personal etc.

Emulsifying

The process where a liquid in which another liquid or substance is finely divided or emulsified but not dissolved. This process is highly possessed by Limitech no matter substance or specific product produced. Over decades Limitech has refined this process to perfection and can assist your process in whatever emulsifying need you may have.

An emulsion is a mixture (dispersion) of two liquids, for example water and oil. Water and oil cannot be mixed by themselves and when you shake them together the two liquids quickly separate again, with the lighter oil on top of the water. By suspending one liquid in another, an emulsion will take form, however, it is not a stable compound and will quickly separate back into 2 phases. Therefore, for it to remain stable, an emulsifier must be used. However, it is possible with the help of emulsifiers to get oil and water to completely unite something easily capable by Limitech’s machines and highly advanced mixers.

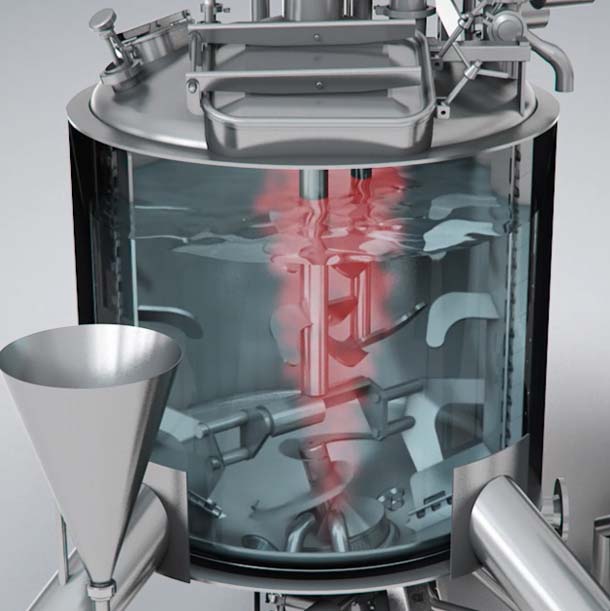

High Shear Mixing

A high shear mixer works as its dissolves and transports one phase into a so-called main phase, this could for example be an ingredient which would normally be immiscible. A stator or a range of blades and stators is used in either a tank or through the pipes where the solution is either mixed or passed to create shear. The High-Shear mixer causes the product to circulate internally in the machine. A high shear mixer is used in several different industries as in the adhesives, food, personal care, pharma, plastic industries, etc. for emulsification, size of particles reduction, dispersion, homogenization, etc.

Homogenizing

At Limitech we are aware, that a consumer wants their individual product to taste the same every time they buy it and not differently depending on when they do. To secure a homogenous product is of great importance when manufacturing products, and you must be sure each batch is completely the same. Systems as well as standalone machines from Limitech is built to guarantee a homogenous product in every process. The mixers run on high speed to break up the fat globules into very fine particles mixing until a homogenous product is secured.

The high-speed Mixer, from Limitech, is mounted in the bottom of the tank in an angle maximizing the mixing effect and allowing the final product to be pumped out from the lowest point of the vessel. When emptying the mixer there is no contact with the mixing unit when turned off, which allows for particles to be emptied out without being destroyed. The Limitech mixer operates like a centrifugal pump and pre-homogenizes the product to make almost instant emulsions and blends. All of Limitech’s products and systems are forged to guarantee a homogenous product. By homogeneous is meant a process of reducing a substance such as the fat globules in milk to extremely small particles and distributing it uniformly throughout a fluid such as milk. For example, when milk is properly homogeneous the cream will not rise to the top. Securing the same product with the exact same taste every time.

Inline Mixing

Limitech’s inline mixer is specially designed to give you a quick and effective blend of liquid ingredients by recirculation and is extremely efficient and will reduces your mixing time tremendously. In-Line mixing ensures the product is passed through the mixer’s stator system before leaving the mixer, which avoids “fish-eyes” or lumps in the product. Inline mixing circulated your product through piping outside of the tank in a safe operation providing you with a short process time and high capacity. Inline mixing requires low maintenance and is build in a compact but sanitary design.

Standard features

–High-shear mixer unit with water flushed seal

–Motor frame with 4 adjustable legs

–Motor and V-belt drive

–Powder funnel

–Connection: clamps and SMS

–Internal surface finish: Ra 0,8

External surface finish: Ra 1,6

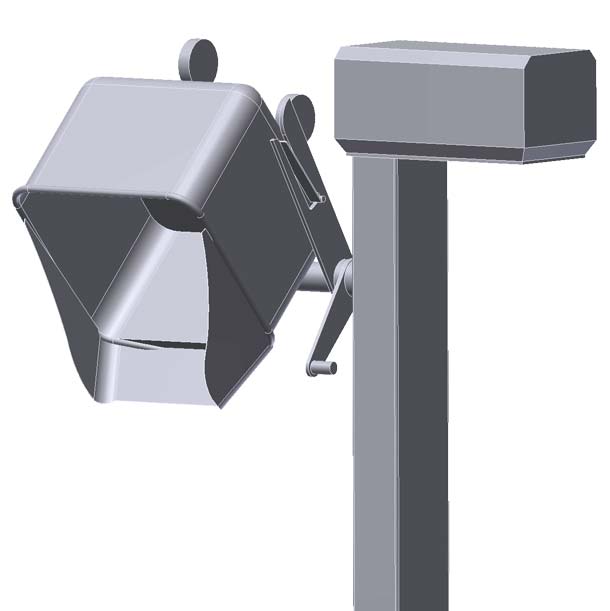

Lifting

Limitech has a bin-lift perfectly suited to relieve you for some of the pressure of manual labor and heavy lifting. The bin lift equipment makes every day easier and a lot less heavy and is a valued addition to machinery to help with the adding of products in your process. It can be installed after your needs either as stand alone or in connection to your fully automated process solution. The lifting bin is beneficial both when it comes to heavy material as it is with working in height.

The bin-lifter works as an electronic helper to lift and emptying the bin into the tank. It is made in stainless steel in AISI 304.

Features:

–Mechanical fall protection

–Control panel

–Electrical load protection

–Start/stop

Emergency stop

Melting

Because of Limitech’s highly developed heating system with both indirect and direct steaming the applications can be customized to your process. Whether your needed equipment is for melting cheese, chocolate or a whole third product Limitech can construct it after your requirements. The melting tanks can be designed to melt products as soy, resin, glue, soap, palm wax, oil and so on.

When selecting a melting tank for your process it is of essence that the needed applications is known. We can construct the tanks whether it is for indirect or direct heat. Depending on you process we can guide you to the best solution for your process.

If heavy scented or colourful substances are to be melted, then it is important that the melter is polished to prevent cross-contamination as well as providing a surface easy to clean.

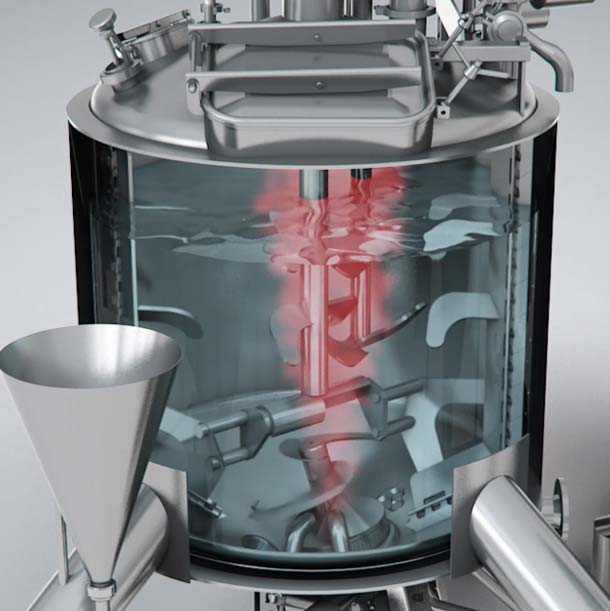

Mixing

Limitech’s mixers are unique process machines that with a highly efficient blend emulsify homogeneously into a single substance. They are used throughout many industries during the manufacturing or processing period. Their powerful tools and blades allow mixers to work with a variety of materials. All mixers can be fitted with different mixing tools that can be changed at all times. This to ensure a multifunctional solution that will serve you for years without running short of options. The range covers functions from fine emulsions with oil droplets down to 1 micron to gentle cooking processes with particles – all in the same tank. All options are suited for very vicious products.

THE MIXING WHEEL:

The High-speed Mixer is mounted in the bottom of the tank in an angle maximizing the mixing effect and allowing the final product to be pumped out from the lowest point of the tank. When emptying the mixer there is no contact with the mixing unit when turned off, which allows for particles to be emptied out without being destroyed. The mixer operates like a centrifugal pump and pre-homogenizes the product to make almost instant emulsions and blends.

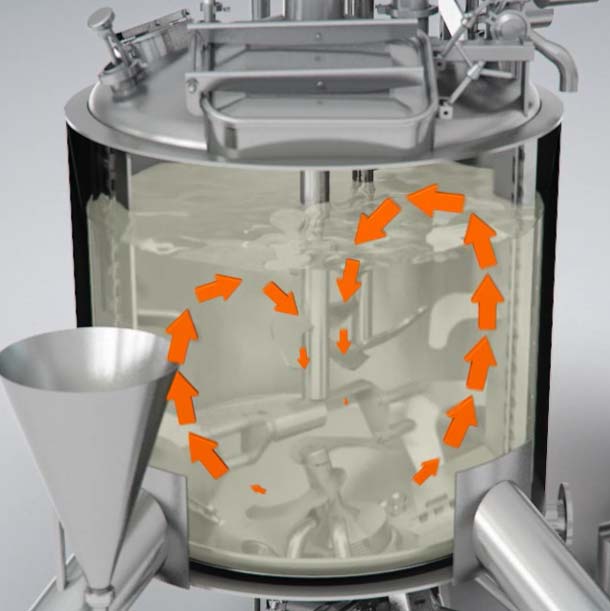

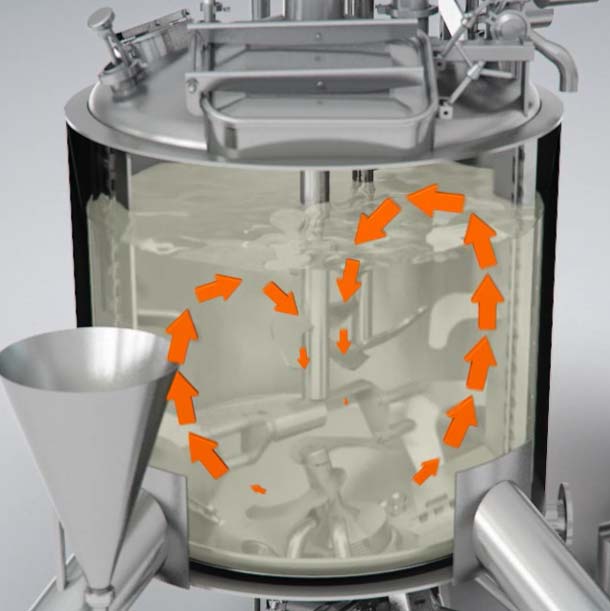

THE AGITATOR

The agitator system is designed to gently and effectively blend without destroying particles and at the same time efficiently scrape the inside tank wall to ensure maximum heating and cooling will transfer into the product. The agitator is equipped with a frequency converter for variable speed control of the motor. The agitator is an important co-player with the mixing tool, that make it possible to handle high viscous products.

Oil Storage

Modern oil storage tanks and dispensing systems are vital tools for continuous processing. Below we’ll discuss oil storage tanks and types of dispensing systems and the different way you can configure them for your needs.

Limitech’s oil storage tanks can be customized to fill your needs of oil storage, whatever scale. We have for example delivered a tank that can hold up to 22,000 Liter oil for mayonnaise production. The tanks can be built with built-in cooling, heating and insulation. The large tanks provide the opportunity of storage for a longer period of time as well as the possibility of level filling.

The 22,000-liter tank can be delivered worldwide as it fits into a 40 feet container. However, Limitech customizes tank sizes to your need of liters.

Pre-Mixing

As the words states pre-mix is used for a substance of ingredients being mixed before use. This is usually done in a tank connected to the main tank in the system. Here parts of the ingredients are mixed before it is led into the main tank for the final process. So, pre-mix thereby usually refers to a substance or object which is mixed in an early stage in the manufacturing and distributing process.

The process of pre-mixing is used as a sub-unit to another process or final process. When a pre-mixer is used together with a process tank. Then pre-mixing gives the advantage to shorten the total process time. This also result in better quality on the final product where the pre-mix solution is used. It also results in better pre-mixture which often result in savings on expensive ingredients because of the better dissolving in the Limitech pre-mixer.

Pressure Cooking

Pressure cooking is the process of preparing and cooking food under high pressure steam, using water or a water-based cooking in a sealed container or tank also known as a pressure cooker. The high pressure limits the liquid to boil and such permits the cooking temperatures well above 100 degrees Celsius to be reached, providing a secure and precise heating. This is an advantage when processing your product.

This process is often between half and a quarter the time for conventional boiling and is thereby extremely effective. When cooked, the steam pressure is lowered back to ambient atmospheric pressure, so that the vessel can be opened safely. Pressure cooking can be used in the process of almost any food that otherwise can be cooked in water-based liquids.

Rasper

Excellent, fast and easy rasping of for example hard, firm and semi-soft cheese blocks up to 18 kg of weight and excellent solution to precut for process cheese production.

Advantages:

–Solid construction

–Easy cleaning

–Rapid cutting

–Outlet height designed for bin or conveyer

Reduction

Reduction is the process achieved when simmering or boiling a liquid until the desired concentration is reached by evaporation. Reduction is reached by boiling rapidly to cause evaporation. When the liquid substance evaporates the substance get both thicker and the flavor intensifies. Reduction can for example be used for meats and vegetables.

Different forms of the liquid will evaporate at a little differentiation in temperatures. This process is also called pulverization. For years, Limitech has perfectionated the different applications and processes and will therefore be a highly valued partner in your reduction process. This describes the traditional method, however, Limitech has managed to do this under vacuum creating a large advantage providing high efficiency in your process. A process used in a lot of industries as food, pharma, personal care, etc.

Shredding

The shredding solutions can be used both as a single machine and in other systems of the process lines we have developed. Limitech’s shredders are at their most impressive in terms of capacity, combining the gentle shredding of raw materials with economical food production.

Limitech’s shredder provides you with an efficient and fast process to make a particular form of different sizes and is used for both separation or for easier and less cost of transportation. A shredder is beneficial in a large number of industries as food, pharma, personal-care, etc. and are therefore beneficial in a lot of different industries.

Limitech’s food processing technologies offers you everything you need to know, when developing a processing line with Limitech’s shredder.

Stirring

Stirring is an important preparation of the homogenization of mixable liquids as well as the gentle stirrup of solid particles in liquids. The differentiated temperature and the concentration of the liquid is highly easier to balance when stirred. Stirring is a very important process in technology and an important process for pharmaceutical and food industries too.

Our different size of agitation and mixer can meet your needs at any production volume. When you stir a solute, the substance is distributed and exposed to more surface area which accelerates the time it takes to dissolve. The Limitech stirring system is an effective and gentle way to keep your product ingredients even distributed and the same temperature in the product mass when stirring before filling. Our agitation system is effective both with a combination of the mixer wheel along with our cooqer line where agitation is the only component. This is the perfect solution for products only needing to be stirred as well as both mixed and stirred.

Ultra High Temperature Treatment

Ultra-high temperature treatment often referred to as UHT, is a type of heat treatment that significantly prolongs the shelf life of liquid foods. The food is heated for 3-5 seconds to a temperature well above 100 degrees C, often 135-145 C. the advantage of the high temperatures is that the treatment time itself can be so short that the product is not damaged. The double injector makes continuous production possible with an easy operating system.

Ultra-high temperature processing (UHT), ultra-heat-treatment or ultra-pasteurization is a food processing technology that almost sterilizes liquid food at a temperature required to kill bacterial endospores, in up to 2 to 5 seconds. This is often done by either:

Direct heating systems

Indirect heating systems

Flash cooling

Homogenization

Vaccum

The vacuum system has three functions, one for deaerating the product, one for avoiding foaming during the process and one for drawing dry or liquid ingredients into the tank under liquid level which makes it a clean, fast and efficient way to add ingredients. The vacuum pump gives you completely power over the mixing of ingredients with its quick suction and high capacity. If you need to boil down a product then you can do it with continuous heating to boiling point. This process can be speeded up by applying the vacuum together with the heating. The vacuum pump will then be sucking the vapouring steam from the product media. The vacuum will then lower the product temperature, and the steam will start heating towards the setpoint again. Then this continuously adding of steam to the jacket will speed up the boil down process.

With vacuum the boiling point can be lowered to 50 degrees Celsius providing you the possibility to fit it to your exact process. Dry ingredients will be added from the bottom of the tank and will be mixed in immediately. No dry products will then lay on top of the liquid product. In combination with a condenser, you can additionally use vacuum to remove moist from a product.

Looking at the advantages of using vacuum you can avoid errors during production, and you will get an end product without burned after-taste, a homogenous product without lumps/fisheyes, rapid process without waste and more filled bottles a glass per hour. The lesser air in the end product makes it easier to bottle, minimize air bubbles in the product and avoid expensive investments in deaerator as the system is multifunctional. Quick reduction of the temperature from 100 to 60 degrees C when using vacuum and cooling in the dimple jacket at the same time. Vacuum can also in combination with condenser cool down faster by evaporating steam/energy from the product.

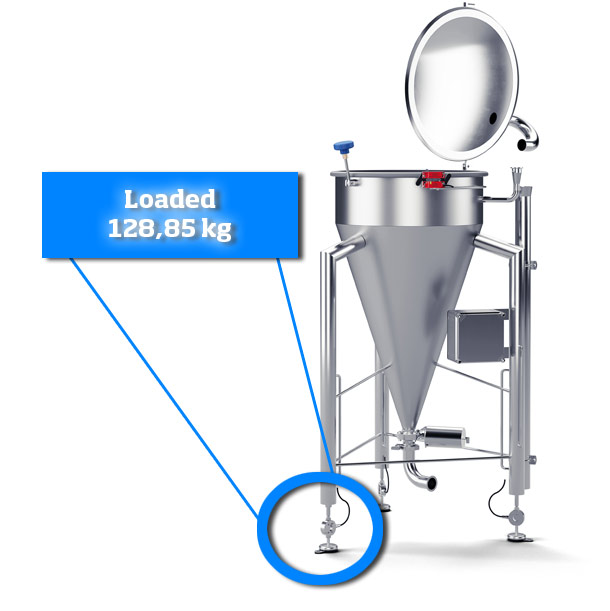

Weighing

By choosing the weighing function from Limitech you can enhance your process productivity by using highly evolved, optimized and developed technology equipment. By integrating intelligent, sophisticated weighing technology into your process on both plant machines and fully automated solutions, manufacturers can achieve the precision required in dry to liquid processing operations – particularly ingredient mixing in liquid batching and blending applications.

To make every minute as effective as possible in you process, electronic scale systems are implemented to increase automation with the use of weight sensors and indicators. This both effectuate your process and secures a non-contaminated product along with no human errors. The automating weighing system provides manufacturers greater control and visibility over the entire process while also securing accuracy. By using weighing technology to more complex processes both in blending and mixing, your facility can experience improved quality control and reduced labor.

The slightest changes in measurements could result in serious impacts of the product both in quality and customer satisfaction. By implementing the weighing system, operators are provided with the possibility to perform frequent quality checks of the product volumes during the process.